[Video] Washroom design: waterproof washroom materials for washroom refurbishments

Waterproof washroom laminate materials

It is essential that washroom materials are waterproof, not just water resistant. All areas of a washroom are exposed to water either through splashing from sinks, urinals, WCs or directly from showering facilities. We prioritise the use of materials that last.

We tested three washroom materials - MFC, HPL and SGL. Two of which we avoid due to their inferior performance.

Do you know which is truly waterproof?

What are MFC, HPL and SGL?

MFC (melamine-faced chipboard) is an engineered wood product made from chipboard and is covered with melamine-infused decorative paper.

HPL (high pressure laminate)is made from moisture resistant chipboard which is then covered with water-resistant decorative laminate and has matching lipping.

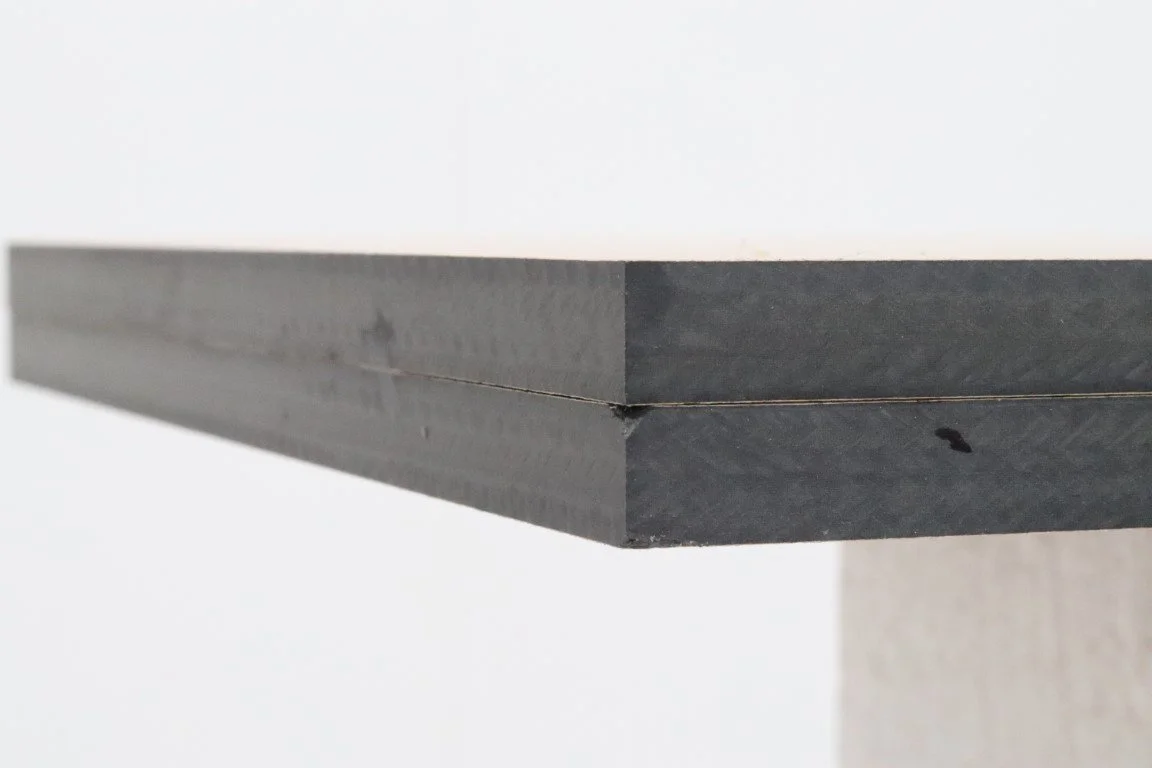

SGL (solid grade laminate) is is a strong, durable, dense and waterproof material made from layers of paper and resin that are compressed together under high heat and pressure.

Water submersion testing

We damaged a panel in a similar way that it would be through general wear and tear of a situation then we submerged panels in water to simulate the build up of water and moisture over a period of time.

For our tests, the panels were submerged for three weeks, however the results we saw are more likely to appear over a longer period of time. These results would appear over a few months if the material is exposed to moisture, for example through shower spray in a changing room.

Water damage

MFC: Before (top) and after (bottom). Material swollen by 3.9mm.

It’s only ever suitable for use in low traffic washroom areas and shouldn’t be used in wet or high moisture areas at all.

HPL: Before (top) and after (bottom). Edge panels soaked off and material swollen by 1.7mm.

HPL is suitable for use in washrooms but not wet areas due to risk of compromise.

SGL: Before (top) and after (bottom) water immersion. No change in material width.

Waterproof and suitable for use in all washroom areas, particularly high traffic areas and wet ones such as showers.

This washroom shows most furniture components made from solid grade laminate. It can also be used for partitions between urinals, benching, splashbacks, lockers and radiator covers.

Durable SGL for washrooms

As SGL is so strong, the initial damage was minimal to the panel which gives the material an initial advantage over the other materials. However, ultimately what this test demonstrates is the difference between SGL that is totally waterproof, and materials which will only perform in a washroom until damaged. When other materials like MFC or HPL are compromised, the damage goes beyond appearance.

Moisture infiltration will cause swelling, weakening the structure for further damage and creating the perfect environment for bacteria to thrive, leading to unpleasant odours and hygiene risks. With SGL, you can trust that the washroom will not only look good but maintain its integrity and hygiene standards, avoiding the issues that come with inferior materials.

For all our washroom refurbs and new projects, we only use solid grade laminate for cubicles, duct panels, vanities, and other components. Its durability, combined with absolute water resistance, ensures that these areas remain hygienic and functional for the long term.

In our next videos, we’ll test material to see which is the best for impact, strength and resistance to fire.

Get in touch

We’ve 25 years experience in designing, manufacturing and installing washroom refurbs. We can advise you on budget, design, compliance and best practice. Contact us here.