[Video] Washroom design: durability of laminate products in washroom refurbishments

Durable washroom laminate materials

At Focus Washrooms, we know that material choice is fundamental to creating a washroom that remains functional, hygienic, and visually appealing for years to come. That’s why we conducted a series of tests to determine which laminate materials offer the best durability for cubicles, duct panels and vanity units.

By selecting the right materials, we ensure that our refurbished washrooms stand the test of time, even in demanding environments.

Ask a question

This washroom features solid grade laminate for most components, used for urinal partitions, benching, splashbacks, lockers, and radiator covers.

Damage testing

The first test in our study focused on simulating the type of damage that could occur if a laminate material, such as a duct panel, were accidentally dropped. Duct panels are typically large and heavy, making them unlikely to be tampered with by washroom users, as they are securely fixed in place using robust clips. However, they are designed to be removable for maintenance teams using suction cups.

While accidental drops are rare in real-world scenarios, this test provides valuable insight into the impact resistance of different materials. To assess durability, we dropped 300 x 300 mm samples of MFC (melamine-faced chipboard), HPL (high-pressure laminate), and SGL (solid grade laminate) from a height of one metre, allowing us to compare their ability to withstand impact and potential damage.

What are MFC, HPL and SGL?

MFC (melamine-faced chipboard) is an engineered wood made of chipboard core with a melamine-infused decorative paper surface.

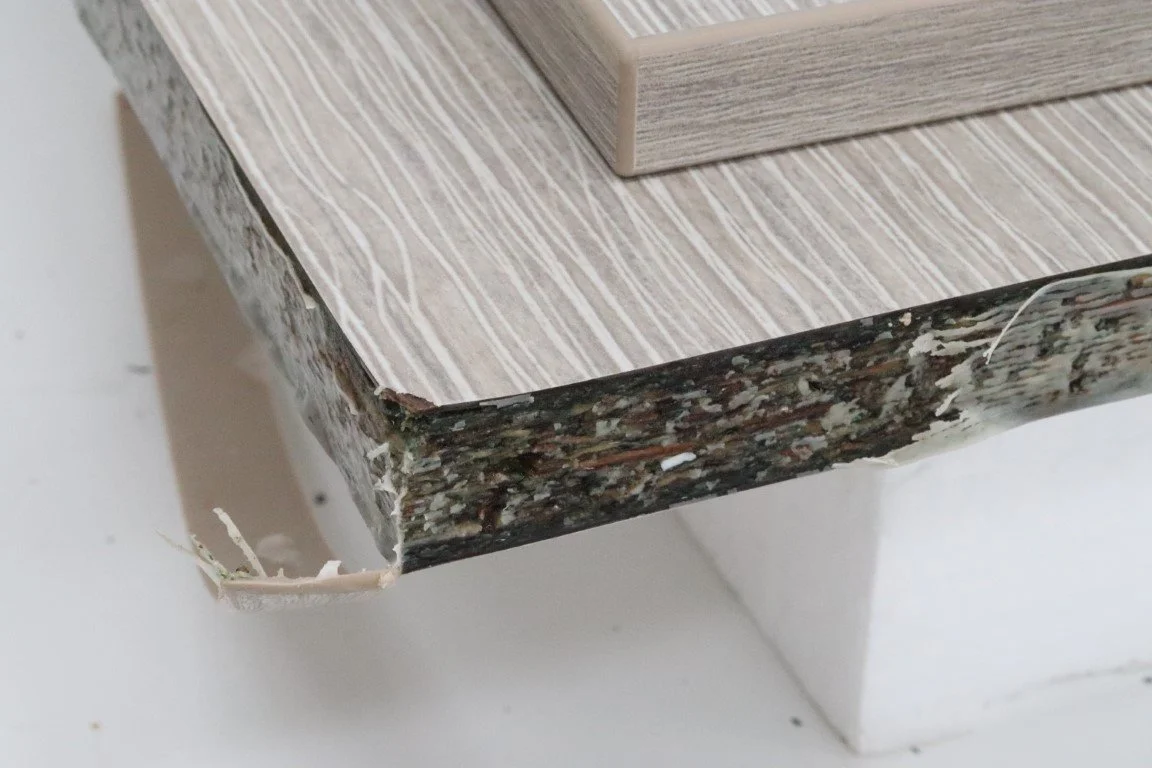

HPL (high-pressure laminate) is moisture-resistant chipboard coated with a water-resistant laminate and finished with matching lipping.

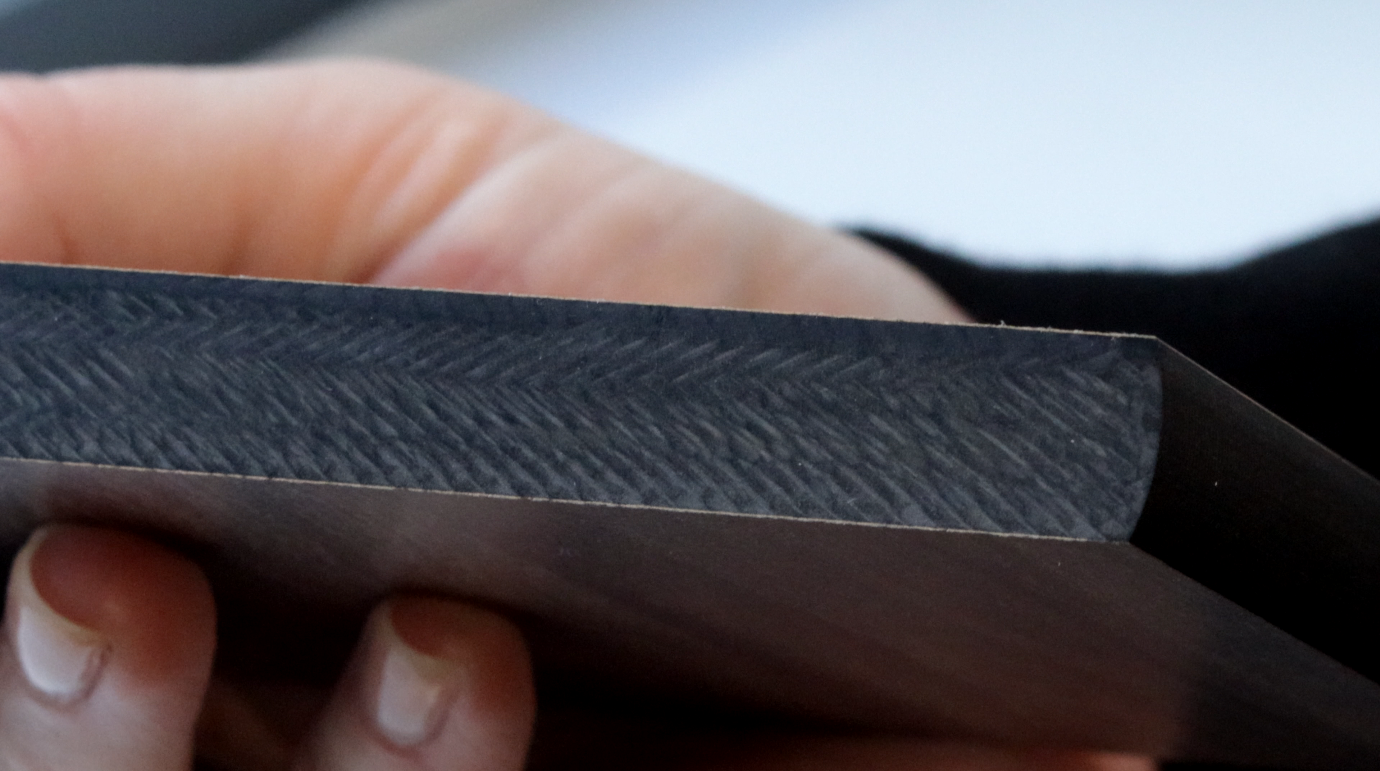

SGL (solid grade laminate) is a strong, durable, waterproof material made by compressing layers of paper and resin under high heat and pressure.

Drop from 1m height

Dropping each material from a 1m height resulted in minor cosmetic damage across all three. SGL showed the least damage, highlighting its superior durability.

MFC

HPL

SGL

SGL remains the best choice

For washrooms and changing rooms where durability and moisture resistance are essential, SGL is the ideal choice. That’s why we use solid grade laminate exclusively for cubicles, duct panels, vanities, and other components in all our refurbishments and new projects. Its strength and water resistance ensure long-lasting hygiene and functionality.

Unlike MFC or HPL, which can suffer structural damage when compromised, SGL prevents moisture infiltration, eliminating the risk of swelling and bacterial growth that leads to odours and hygiene risks. Its durability ensures that washrooms maintain both their appearance and integrity, avoiding the pitfalls of inferior materials.

While our team was already confident in SGL’s superior performance, the results of the test speak for themselves. The impact resistance, durability, and moisture-proof qualities make it the clear choice for long-term washroom reliability.

In our next videos, we’ll be testing materials to see which performs best for water resistance, strength, and fire resistance.

Water damaged HPL

Swollen MFC due to water ingress